LOCATION

South Piedmont Community College

3509 Old Charlotte Highway

Tyson Family Center for Technology

Monroe, NC 28110

Room 1407

CONTACT INFORMATION

5S Workshop & Simulation

Description

5S Workshop with Simulation: Streamlining Efficiency on the Machining Floor

Duration: 4 Hours

Target Audience:

This workshop is ideal for production managers, supervisors, operators, and employees working in manufacturing environments, particularly those on the machining floor. It is designed for individuals seeking to enhance workplace organization, efficiency, and safety through the application of the 5S methodology.

Course Overview:

The 5S methodology is a foundational Lean tool used to improve workplace organization and efficiency. This 4-hour hands-on workshop combines instruction with a practical simulation on the machining floor, allowing participants to apply 5S principles in a real-world setting. Through this immersive experience, participants will learn how to implement 5S to reduce waste, improve safety, and create a more organized and productive work environment.

Course Objectives:

Introduction to 5S Methodology:

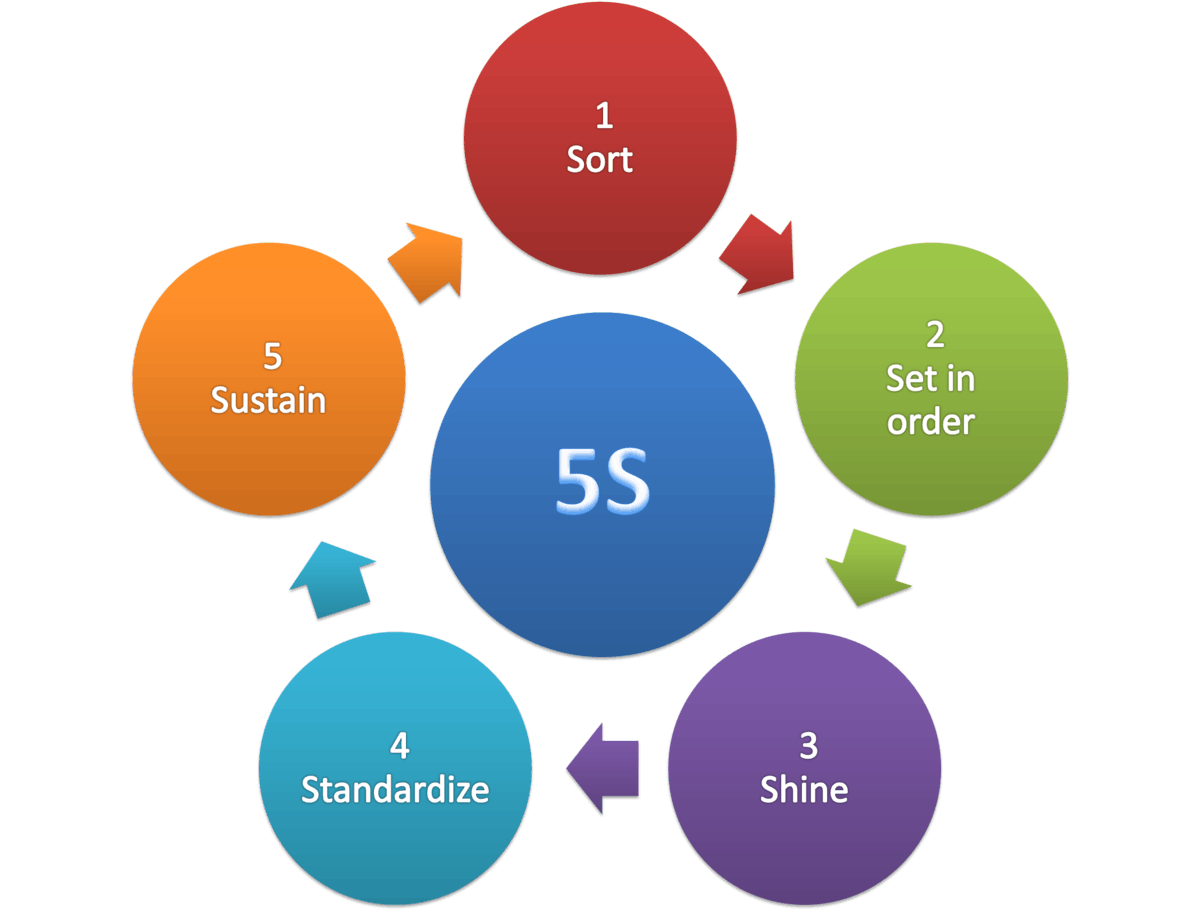

- Understand the five pillars of 5S (Sort, Set in Order, Shine, Standardize, Sustain) and their importance in a manufacturing environment.

- Learn how 5S supports Lean manufacturing principles and contributes to continuous improvement.

Implementing 5S on the Machining Floor:

- Gain practical insights into how to apply each step of 5S in a machining environment.

- Learn strategies for sorting tools, materials, and equipment, setting them in order for optimal workflow, and maintaining a clean and organized workspace.

5S Simulation Exercise:

- Participate in a live simulation on the machining floor, applying the 5S principles in a controlled environment.

- Work collaboratively to identify areas of improvement, implement 5S strategies, and measure the impact on efficiency and safety.

Sustaining 5S and Continuous Improvement:

- Develop a plan to standardize 5S practices and ensure they are sustained over the long term.

- Learn how to engage team members and foster a culture of continuous improvement through regular audits and ongoing training.

Action Planning for Workplace Integration:

- Create a personalized action plan to implement and sustain 5S in your own work area.

- Receive feedback and guidance on how to overcome challenges and achieve lasting results.

Interactive Learning Experience:

This workshop features a combination of instruction, hands-on activities, and a real-world simulation. Participants will have the opportunity to practice the 5S methodology in a supportive environment, gaining the confidence to apply these principles in their daily work.

Why Attend?

By attending this workshop, you’ll acquire the skills and knowledge needed to implement 5S effectively in your workplace. This hands-on experience will empower you to enhance workplace organization, improve efficiency, and create a safer, more productive machining floor.

Join us for this practical and engaging workshop, and take the first step towards streamlining operations and fostering a culture of continuous improvement in your facility.